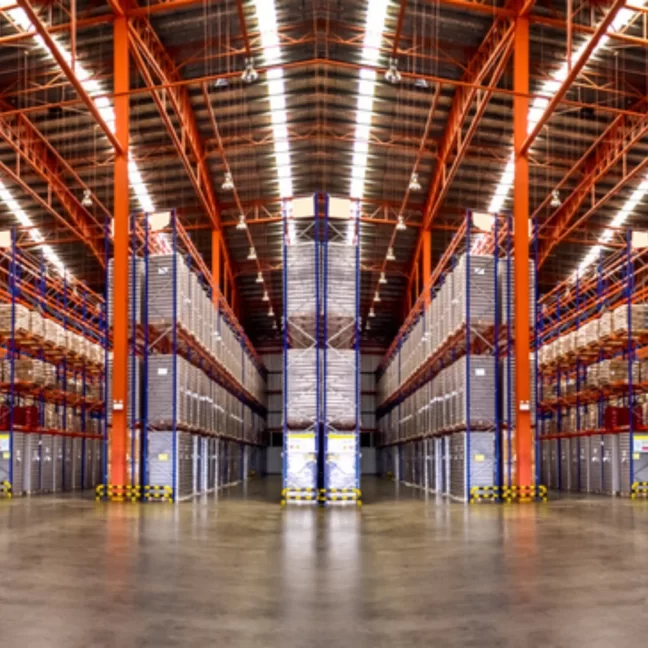

Inventory represents this portion of your working capital invested in purchased or finished goods ready to be sold or used for further processing. It is basically the oversight of operations in a warehouse, which includes receiving, tracking, and storing inventory, as well as training staff, managing shipping, workload planning, and monitoring the movement of goods. SC endeavors to help its clients to effectively manage their warehouses in an optimized fashion to help the operations on one hand, and to ensure the best utilization of resources invested in inventory. Warehouses are more often referred to as Fulfillment or Distribution centers. Having a physical location to store your goods or finished products is just one element. How you manage your fulfillment center, impacts how successful your whole business model can be.

Warehouse management refers to the overall process which oversees the location (s), where stocking, goods receiving, barcoding, storage, issuance, and replenishments take place. To summarize, the warehouse processes could be identified as: Receiving & Stowing, Picking & Packing, Shipping, Inventory Tracking, and Reporting.

A warehouse management system (WMS) is software designed to optimize operational processes in a warehouse. By implementing a WMS, the business will have full visibility into real-time inventory levels and storage, staff productivity, demand forecasting, and order fulfillment workflows within a warehouse.

Because warehouse processes are so complicated and expensive, many brands choose to outsource the entire fulfillment process to a third-party logistics (3PL) company. Unlike an on-demand warehousing company that finds warehouses with excess space, 3PLs run their own fulfillment centers.